Designed for conveyors, this industrial depositor from Unifiller features a patented SV valve, large openings, precision height adjustment and angled surface covers. The pneumatic control system works in cold environments to reduce damage caused by moisture build-up, caustic cleaning processes, and daily wear and tear. The company suggests pairing the depositor with a dripless nozzle for accurate deposits of viscous products like cream, yogurt, cheesecake and soft cheese into various containers, trays, or onto ready meals. It can be easily integrated into existing production or FFS lines. It can also be combined with the Unifiller hopper topper, a unique product pumping system designed for transferring dairy products. Equipped with an optic product sensor, the company says it maintains precise hopper levels and adjusts pump speed through flow control to eliminate fluctuating deposit weights.

More InformationEquipment suppliers highlight the latest advances in fillers and cappers.

EQUIPMENT SHOWCASE

Unifiller

FILTEC

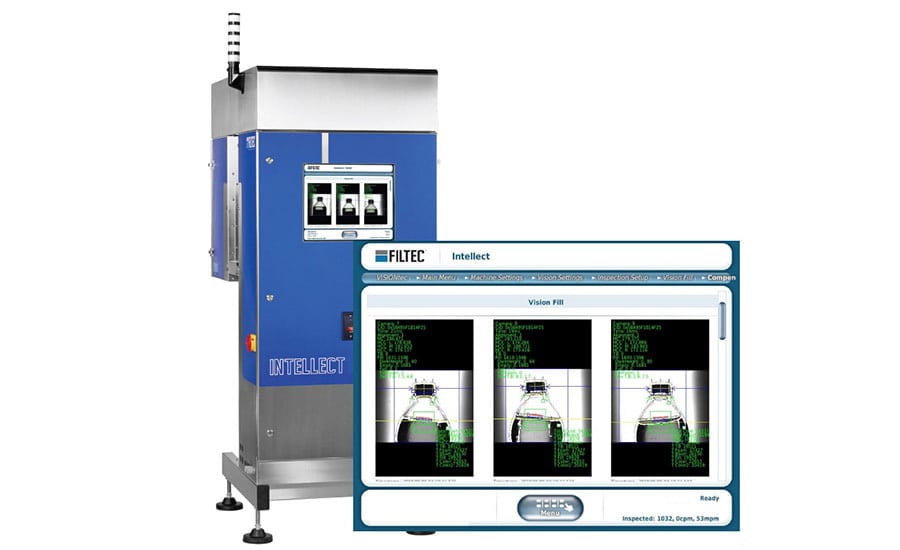

FILTEC's Filler Management Solution comprises advanced photon and vision systems that monitor filler performance in real-time, ensuring precise fill levels for glass, PET bottles, and aluminum cans. While operating at speeds up to 2,500 containers per minute, the company’s technology swiftly detects underperforming valves, preventing product loss and maintaining line efficiency. Integrated with the Intellect platform, the company says its solutions provide comprehensive, scalable inspection capabilities, giving manufacturers actionable insights to optimize production.

Mo

Filler Specialties

Filler Specialties designs and manufactures a full line of sanitary rotary bottle filling and capping equipment for fluid milk and related flowable products. Updated features include a polished stainless-steel base with stainless-steel baseplate for long life; open stainless- steel carriage design for ease of cleaning; and electric bowl and capper raising and lowering available with presets to ease bottle size changeovers. All machines include a dependable gear drive system; external mount filling valves; optional clean-in-place valves; electronic level control; and capping turrets including pick and place.

More InformationAll content and images were provided by their respective companies. Used with permission. Company links available in the Editorial Index.